All About Salt Spray Corrosion Tester Chamber

Corrosion is a major concern in many industries, leading to material degradation and reduced product lifespan. A Salt Spray Corrosion Tester Chamber is an essential tool used to evaluate the corrosion resistance of materials and coatings Corrosion is a natural process where metals deteriorate due to environmental factors like moisture, oxygen, and salt. This process […]

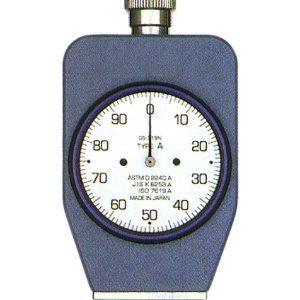

Understanding Durometer Type A and D

Durometers are essential instruments used to measure the hardness of various materials. They help industries ensure quality, performance, and durability of products, especially polymers, elastomers, and plastics. Among the different types of durometers, Type A and Type D are the most commonly used, each designed for specific materials and applications. What is a Durometer? A […]

What Is Flex Abrasion (Scrub) Tester

Abrasion refers to the gradual wearing down of material due to friction or repeated contact. This process affects everything from fabrics to metals, reducing their usability and lifespan. Abrasion testing is essential for industries that rely on durable materials. It helps predict the lifespan of a product, ensuring safety, reliability, and cost-effectiveness. Components of a […]

What is Temperature And Humidity Transmitter

A temperature and humidity transmitter is a device that is used to measure and transmit temperature and humidity data to a remote location. It typically consists of sensors for measuring temperature and humidity, as well as a transmitter that sends the data to a receiver or other monitoring system. The transmitter may be connected to […]

Guide About A Microbial Air Sampler

A microbial air sampler is a device used to collect and analyze airborne microorganisms in a specific environment. These devices are often used in research and industrial settings to monitor the quality of the air, identify potential sources of contamination, and assess the effectiveness of air cleaning and sterilization systems. There are several types […]

What Are Abrasion Testers?

Abrasion testers are machines used to measure the resistance of a material to abrasion, which is the process of wearing away a surface through rubbing or friction. Abrasion testers are commonly used in a variety of industries, including textiles, automotive, and construction, to evaluate the durability and performance of materials. There are several types […]

What are Impact Testers?

Impact testers are mechanical devices used to measure the resistance of materials to impact, which is the force of an object striking a surface or a material experiencing a sudden change in motion. Impact testing is a common method used to evaluate the toughness and ductility of materials, as well as their ability to absorb […]

Applications and Types of Anemometer

The anemometer is an instrument used in weather stations that measures wind speed or calculates current gases. An anemometer that is mechanical with a disc whose angle of inclination was put perpendicular to the wind direction was used. This determines the velocity of the wind as well as the wind direction based on the disc’s […]

Information About pendulum Skid Tester

A skid tester, also known as a pendulum skid tester or pendulum friction tester, is a device used to measure the coefficient of friction of a surface. This measurement is important in various industries, as it helps to determine the surface’s level of traction or slip resistance. One common application of skid testers is […]

A Beginners Guide About Anemometer

An anemometer is an instrument used to measure wind speed and is often used in weather stations. There are many different types of anemometers, but they all work by measuring the force of the wind on a rotating or moving object. Meteorologists use anemometers to help them predict weather patterns and forecast storms. Wind speed […]