Laboratory Glove Box – Questions & Answers

Q1: What are the primary applications of a laboratory glove box?

A laboratory glove box is used for handling sensitive materials in a controlled environment. Primary applications include:

- Inert atmosphere work – performing experiments in oxygen-free and moisture-free conditions (e.g., using argon or nitrogen).

- Hazardous material handling – safely managing toxic, radioactive, or biohazardous substances.

- Electronics and semiconductor fabrication – preventing oxidation or contamination.

- Pharmaceutical and medical research – working with sterile or highly reactive compounds.

- Material science – studying air- or moisture-sensitive chemicals, catalysts, or nanomaterials.

Q2: What are the key safety features to look for in a glove box?

Important safety features include: –

- Gas-tight seals to prevent leaks.

- Pressure control systems to maintain positive or negative pressure depending on the application.

- HEPA or ULPA filtration for hazardous particulate containment.

- Gas purification systems to maintain low oxygen/moisture levels.

- Emergency purge systems for rapid atmosphere exchange in case of contamination.

- Ergonomic glove ports to reduce operator fatigue and improve precision.

Q3: How do you maintain and clean a glove box?

- Routine cleaning – Use lint-free wipes and approved solvents compatible with the materials inside.

- Glove inspection – Regularly check for tears or wear; replace damaged gloves immediately.

- Gas system maintenance – Monitor and replace purification cartridges when needed.

- Sensor calibration – Keep oxygen and moisture sensors calibrated for accurate readings.

- Scheduled servicing – Follow the manufacturer’s maintenance guidelines for seals, pumps, and filters.

Q4: What are the main differences between an inert atmosphere glove box and a biological safety cabinet?

- Inert atmosphere glove box: Maintains a sealed environment filled with gases like argon or nitrogen to protect oxygen- and moisture-sensitive materials.

- Biological safety cabinet (BSC): Designed to protect both the user and the environment from biological agents, using HEPA filtration and airflow.

- Key difference: Glove boxes are completely sealed with gloves attached to ports, while BSCs use open front access with airflow containment.

Q5: How is the inert atmosphere (e.g., argon, nitrogen) maintained and monitored within a glove box?

- Gas supply – Connected to high-purity gas cylinders.

- Circulation and purification – Gas passes through purification columns that remove oxygen and moisture.

- Sensors – Integrated oxygen and moisture analyzers monitor levels in real time.

- Automatic control systems – Adjust purge and recirculation rates to maintain stable conditions.

Q6: What are the common materials used for the glove box enclosure and gloves, and how does the material choice affect its application?

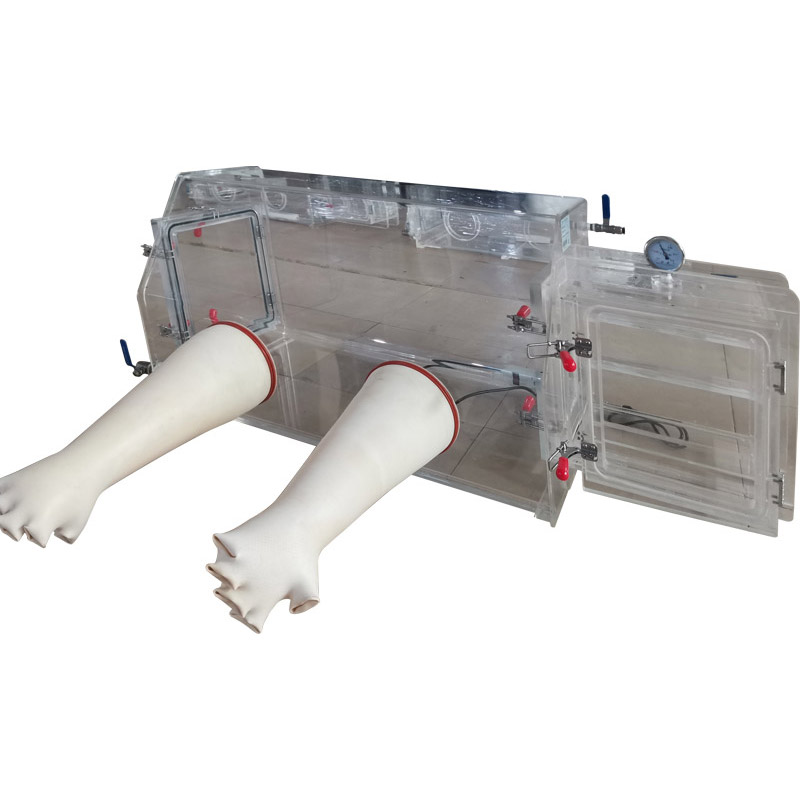

- Enclosure materials: Stainless steel (durable, corrosion-resistant), acrylic (clear visibility, cost-effective), polycarbonate (impact-resistant).

- Glove materials: Butyl rubber (chemical resistance), neoprene (abrasion resistance), hypalon (broad chemical resistance), natural rubber (high flexibility).

- Impact on application: Choice depends on chemical compatibility, visibility requirements, and mechanical durability.

Q7: Can you explain the function of the antechamber and the gas purification system?

- Antechamber: A small transfer compartment that allows materials to be moved in or out without disturbing the main atmosphere.

- Gas purification system: Removes oxygen, moisture, and other contaminants using molecular sieves, catalysts, and filters to maintain an inert environment.

Q8: What is the maximum achievable oxygen and moisture level inside an inert gas glove box?

- Oxygen: Typically <1 ppm, with high-end systems reaching <0.1 ppm.

- Moisture: Typically <1 ppm, with specialized systems achieving <0.1 ppm.

Performance depends on purification efficiency, system integrity, and proper operation.

Q9: How is a glove box typically integrated with other analytical instruments like a microscope or a mass spectrometer?

- Direct integration – Instruments are installed inside the glove box for real-time analysis without exposure to air.

- Sealed feedthroughs – Electrical, optical, or mechanical connections pass through airtight ports to external equipment.

- Custom modifications – Some glove boxes have built-in vibration isolation, optical windows, or extended compartments to house specialized instruments.