The 36+ PTV benchmark

For typical pedestrian traffic where floors can be wet or contaminated, aim for a minimum PTV of 36 or higher. In the HSE/UKSRG risk model, PTV ≥ 36 is classified as “low slip potential,” which is the benchmark dutyholders target to demonstrate a safe walking surface in wet use.

Why “wet” changes everything

On clean, dry floors, many surfaces exceed 36 without trying. The real test is final conditions of use—when moisture, films, and contaminants are present. That’s why authorities specifically recommend targeting 36+ in wet conditions rather than relying on dry results.

PTV 101: What the Number Actually Means

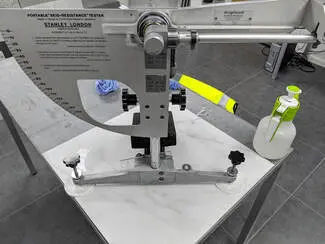

How the pendulum works

The British pendulum simulates a heel strike with a standardized rubber slider swinging over the surface. The deceleration is translated into a Pendulum Test Value (PTV)—a higher number means more available friction and lower slip risk. It’s portable and designed for field conditions where slips actually happen.

British Standard BS 7976 and HSE’s preference

The test method is codified in BS 7976 Parts 1–3. Importantly, HSE identifies the pendulum as its preferred assessment method, used both in lab and in-situ, dry and contaminated.

Risk Bands Used by HSE/UKSRG

High, Moderate, Low slip potential bands

HSE reproduces the UKSRG bands as a quick way to interpret results:

- 0–24 PTV: High slip potential

- 25–35 PTV: Moderate slip potential

- 36+ PTV: Low slip potential

These bands underpin the industry’s “≥36 when wet” target.

How testers interpret your certificate

When a report shows 36+ under wet/contaminated conditions (and states the slider, orientation, and method), specifiers and investigators typically regard the surface as suitable for general pedestrian use. UKSRG also treats 36+ as the threshold for “low risk.”

Why 36+ in Wet Conditions Is the Practical Minimum

Fluid film & heel strike physics

At heel strike, a thin fluid film can separate sole and floor—exactly when slips ignite. The pendulum recreates that, so wet PTV captures the problem dry tests miss.

Indoor vs. outdoor, public vs. private spaces

Busy public zones (retail lobbies, station concourses, hospital corridors) need resilience against rain, tracked-in moisture, and cleaning residues. That’s why guidance says: specify 36+ in wet final use—not just in pristine, ex-factory dry labs.

The Variables That Can Push You Below 36

Contaminants: water, oils, food

Different contaminants vary in viscosity and film thickness, altering friction. Neutral pH water can be enough; oils and food greases are worse, requiring even more micro-texture or treatment to maintain 36+.

Slope and drainage

Even a gentle slope reduces effective safety margins. As a rule of thumb, practitioners often increase the target by ~1.75 PTV per 1° of slope. So if a corridor has 3° fall, your wet target might be ~36 + (1.75×3) ≈ 41–42 PTV.

Footwear and pedestrian behavior

Fast turns, running, and compromised tread reduce friction. Environments with hurried traffic (transport hubs, stadiums) often set headroom above 36 to absorb real-world behavior.

Surface Micro-Roughness (Rz) and How It Supports PTV

Rz thresholds for wet areas

HSE pairs pendulum results with Rz micro-roughness to strengthen conclusions for water-wet areas:

- Below 10 µm: High slip potential

- 10–20 µm: Moderate

- 20+ µm: Low

Tracking Rz helps explain drops in PTV over time and validates cleaning/maintenance strategies.

Pairing PTV with Rz for confidence

If your floor consistently hits ≥36 PTV (wet) and shows Rz ≥20 µm, you’ve built redundancy into your slip-resistance story—useful for procurement sign-off and incident defense.

Specifying Flooring to Achieve ≥36 Wet

What to ask manufacturers and suppliers

Ask for independent BS 7976-2 certificates reporting PTV (wet) with slider type, direction, and site preparation. You want in-use conditions (post-grout, post-seal, realistic cleaning), not just ex-factory samples.

Wording that avoids ambiguity

A clear spec line might read:

“Minimum PTV 36+ in wet conditions when tested to BS 7976-2 with Slider 96 (4S), in final use state.”

Authorities explicitly encourage such wet PTV specification for final conditions.

Testing Protocols That Stand Up to Scrutiny

Slider choice (#96 / #55) and directions

Use Slider 96 (4S) for shod pedestrians (most public areas). Use Slider 55 in barefoot zones (e.g., pool surrounds). On profiled floors, test multiple directions to capture troughs and peaks.

Sampling, cleaning state, and environment

Document exact locations, cleaning state, contaminant used, ambient conditions, and orientation. Courts and inspectors look for these details to validate an “apples-to-apples” comparison.

Interpreting Test Reports Like a Pro

Reading the tables and notes

Look for: PTV wet, slider ID, number of swings, mean/median, standard deviation, direction, and site notes. Absence of any of these can weaken the evidence trail.

Spotting red flags in “dry-only” claims

“PTV 50 (dry)” sounds impressive—but may crash to <30 when a film of water appears. Only wet PTVs (or validated contaminant equivalents) prove suitability for real-world use.

Maintenance: Keeping a 36+ Floor at 36+

Cleaning regimes and chemistry

Residues (detergent films, polish) fill micro-texture and lower PTV. Use manufacturer-approved, low-residue detergents, verify with spot testing, and document the schedule. Rz trending is your early-warning system.

Wear, polishing, and coatings

Traffic wear, crystallization, or inappropriate coatings can reduce texture. Where feasible, choose treatments that increase micro-roughness without creating cleaning problems—then re-test.

Designing Out Risk

Entrances, matting, and walk-off zones

Trap water before it reaches smooth interior finishes. Multi-stage entrance matting with adequate length protects your PTV margin.

Drainage, falls, and water management

Where water is inevitable, design falls and drainage to prevent pooling. Remember the slope adjustment to your target PTV.

Legal, Insurance, and Compliance Angles

Evidence that convinces investigators

HSE emphasizes pendulum testing with UKSRG-aligned interpretation. Pair PTV ≥36 wet with Rz data and an HSE SAT assessment for a robust, transparent risk profile.

Common pitfalls in claims and defenses

- Relying on dry-only certificates

- No documented cleaning regime

- Ignoring slopes and entry water sources

- Using non-representative contaminants in testing

Practical Checklist

Pre-installation

- Demand BS 7976-2 wet PTV ≥36 on the actual product finish.

- Review Rz and supplier maintenance guidance.

Post-installation

- Test in situ after grouting/sealing.

- Confirm ≥36 wet in all critical directions; document slider, conditions.

In-service monitoring

- Re-test periodically, especially after chemistry changes or refurbishments.

- Track Rz and audit cleaning performance.

Real-World Scenarios

Retail entrance in winter

Track-in water spikes; choose textured surfaces that achieve ≥36 wet, extend matting, and boost your target on slopes and ramps.

Commercial kitchen pass-through

Oil mist and food residues are more viscous than water; keep PTV headroom above 36, upgrade cleaning chemistry, and consider textured or treated finishes.

Pool-adjacent corridors (shod vs. barefoot)

For shod areas, Slider 96 and ≥36 wet apply. True barefoot zones may require Slider 55 and different criteria—ensure tests match the use case.