SlipTest – Servicios de Pruebas de Resbaladicidad en Pisos

Garantizando la Seguridad del Suelo con el Probador de Péndulo Los resbalones y tropiezos son una de las principales causas de lesiones en el lugar de trabajo y reclamaciones por responsabilidad civil. Garantizar la seguridad del suelo no solo es un requisito legal, sino también un factor crucial para mantener un entorno seguro para empleados, […]

SlipTest – Bodenrutschtests

Sicherheit auf Bodenflächen mit dem Pendeltester gewährleisten Rutsch- und Stolperunfälle gehören zu den häufigsten Ursachen für Arbeitsunfälle und Haftungsansprüche im öffentlichen Bereich. Die Gewährleistung der Bodensicherheit ist nicht nur eine gesetzliche Verpflichtung, sondern auch ein entscheidender Faktor zur Schaffung einer sicheren Umgebung für Mitarbeiter, Kunden und Besucher. SlipTest ist auf professionelle Tests zur Rutschfestigkeit von […]

SlipTest – Services de Test d’Adhérence des Sols

Assurer la Sécurité des Sols avec le Testeur à Pendule Les glissades et les chutes comptent parmi les principales causes de blessures sur le lieu de travail et de réclamations en responsabilité civile. Assurer la sécurité des sols n’est pas seulement une obligation légale, mais aussi un élément essentiel pour maintenir un environnement sûr pour […]

Floor Slip Testing Services in France

Slip and fall accidents are a major concern in commercial, industrial, and residential environments. Ensuring the safety of flooring surfaces is crucial in preventing accidents, reducing liability risks, and complying with safety regulations. SlipTest provides professional floor slip testing services in France, using the Pendulum Tester, the globally recognized standard for measuring slip resistance. Why […]

SlipTest – Floor Slip Testing Services

Ensuring Floor Safety with the Pendulum Tester Slips and trips are among the leading causes of workplace injuries and public liability claims. Ensuring floor safety is not only a legal requirement but also a critical factor in maintaining a safe environment for employees, customers, and visitors. SlipTest specializes in professional floor slip resistance testing services, […]

Tile Safety-10 Reasons Why Slip Resistance Matters

10 Reasons Why Slip Resistance Matters 1. Safety First Slips are an extremely common cause of injury and result in thousands of hospital admissions each year. Tiles that are wet, contaminated or poorly designed will increase the likelihood of an accident occurring. 2. Be Compliant There are various standards and guidelines which describe how to […]

Ramp Test vs Pendulum

It is not uncommon to find slip ratings on flooring products such as tiles and laminate. These are usually represented as R-values or Pendulum Test Values (PTV). Whilst many flooring professionals rely on R-values or PTV as a measure of slip resistance, these are commonly misunderstood. Following guidance by the Health & Safety Executive (HSE) and […]

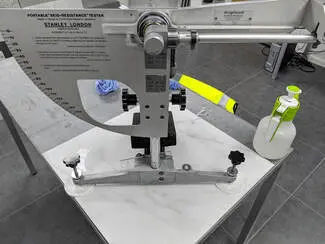

Pendulum Accessories Kit

The Munro Stanley Pendulum Tester is built to last. Providing the instrument is regularly serviced and calibrated, it is capable of providing several decades of service with no deterioration in the quality of the results. As with all precision instruments, it is important that the Pendulum Tester is carefully prepped prior to use. Failure to […]

Safety in the Workplace

Employers are responsible for the health-and-safety rights of their employees. This is enforceable in the UK under the Health and Safety at Work Act 1974. Companies who fail to comply are at risk of legal action, fines, payouts, raised insurance premiums and, in the most serious cases, imprisonment. Make sure you take health and safety seriously. Keep you […]

Slip Risk in Restaurants

Slips and trips are a common cause of injury and fatality in the restaurant industry. These are usually as a result of spillages and poor cleaning practices. Companies are required by law to protect the health and safety of their employees and anyone who may be affected by their work. There are a number of […]